WHAT IS HOT TWIST & INDUCTION TWIST?

STEEL MATERIALS IN DIFFERENT DIAMETER AND SHAPES

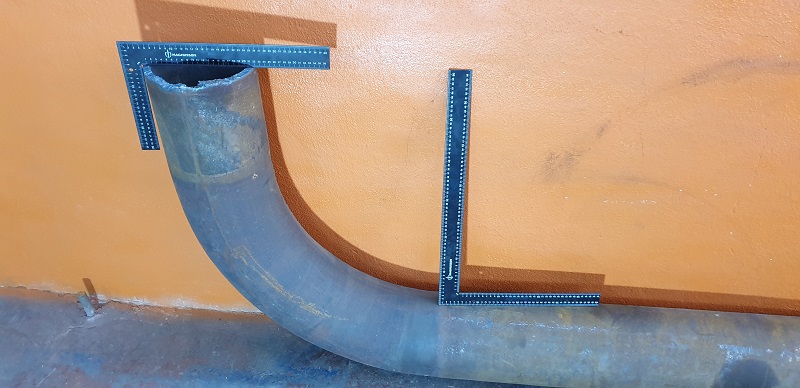

WITHOUT DEPENDING ON ANY MOLD, AT THE DESIRED ANGLE AND RADIUS

NOT A COMPETITOR OF OTHER TWISTING METHODS THAT PROVIDE BENDING

IT IS AN ALTERNATIVE METHOD.

WHY HOT TWIST?

THIS METHOD IS DIFFERENT FROM OTHER TWISTING METHODS

THERE IS A WAY OF WORKING.

PRODUCT BENDING SHAPE SIMILAR TO MANDOW BENDING MACHINES

IT DOESN'T NEED A MOLD TO BEND EVEN IF IT SHOWN.

MANY MATERIALS IN DIFFERENT SHAPES BECAUSE THERE IS NO NEED FOR MOLDS

CAN MAKE BENDINGS.

ADJUSTMENT CAN BE MADE FOR ALMOST EVERY mm REGARDING THE RADIUS.

IT HAS ANGLE RANGE OF 180 DEGREES FROM 5 DEGREE ANGLES.

TWISTING WORKS FOR MULTIPLE PRODUCTS WITH BALL THICKNESS OVER 3mm

ATTACHED TO EXPENSIVE MOLDS. WITH HOT TWIST THESE MOLD PROBLEMS

IT PROVIDES EXCEEDING AND PROVIDES ADVANTAGE TO THE MANUFACTURER.

DURING BENDING, BECAUSE THE BENDED MATERIAL IS SUBJECT TO HEAT

THERE IS NO LOSS IN THE FORM OF PROFILE.

WHAT PRODUCTS ARE USED FOR HOT TWISTING?

WALL THICKNESS 3mm AND OVER ALL STITCHED, SEAMLESS STEEL PIPES

I IRONS

U IRONS

COMMENTS

BOX PROFILES ON RECTANGULAR AND SQUARE PRODUCTS

OUR PRODUCTION RANGE

IN PIPES:

OUTER DIAMETER: ALL DIAMETER BETWEEN DIAMETER 60mm FROM DIAMETER 273MM

BALL THICKNESS: BETWEEN 3mm AND 25mm

BOX PROFILES:

SQUARE AND RECTANGULAR: FROM 60X60mm to 250X250MM

ALL DIMENSIONS BETWEEN

I -U- AND COMMENTS

ALL DIMENSIONS BETWEEN 60mm AND 250mm

RADUUS

MIN HALF DIAMETER: 150mm

MAX HALF DIAMETER:1,400mm

TWIST ANGLE

MIN ANGLE: 5 DEGREES

MAX ANGLE: 180 DEGREES